Babcock & Wilcox’s (B&W) Thermal segment has secured a full notice to proceed with a significant coal-to-natural gas conversion project in the US.

Valued at approximately $246m, the development is part of AES Indiana’s initiative to transition away from coal and cut carbon dioxide emissions at its Petersburg Generating Station.

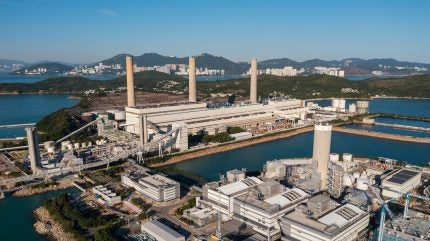

The conversion of the 1.16GW Petersburg plant’s two coal-fired boilers to natural gas is expected to significantly reduce the facility’s carbon footprint.

B&W Thermal is tasked with designing and installing the new natural gas system, air systems, and additional equipment.

B&W Thermal senior vice-president Chris Riker said: “We began engineering and design work earlier this year and are pleased to be moving forward with this important project for AES Indiana.

“We continue to see significant interest from utilities in the US and elsewhere that want to switch from coal to cleaner fuels, such as natural gas, to significantly reduce greenhouse gas emissions and the overall environmental impact of their generating assets.”

Meanwhile, B&W Construction (BWCC) will manage the construction aspect of the endeavour.

Further contributing to this project, B&W FPS, a subsidiary of B&W, will provide essential components such as burners, ignitors, and controls.

The project’s timeline is set for completion by the first quarter (Q1) of 2027.

Riker added: “This large, complex project will be coordinated across several B&W business segments, including our B&W Thermal, BWCC and FPS businesses.

“Our depth of knowledge and expertise allows us to smoothly and efficiently execute large, complex fuel-switching projects such as this.”