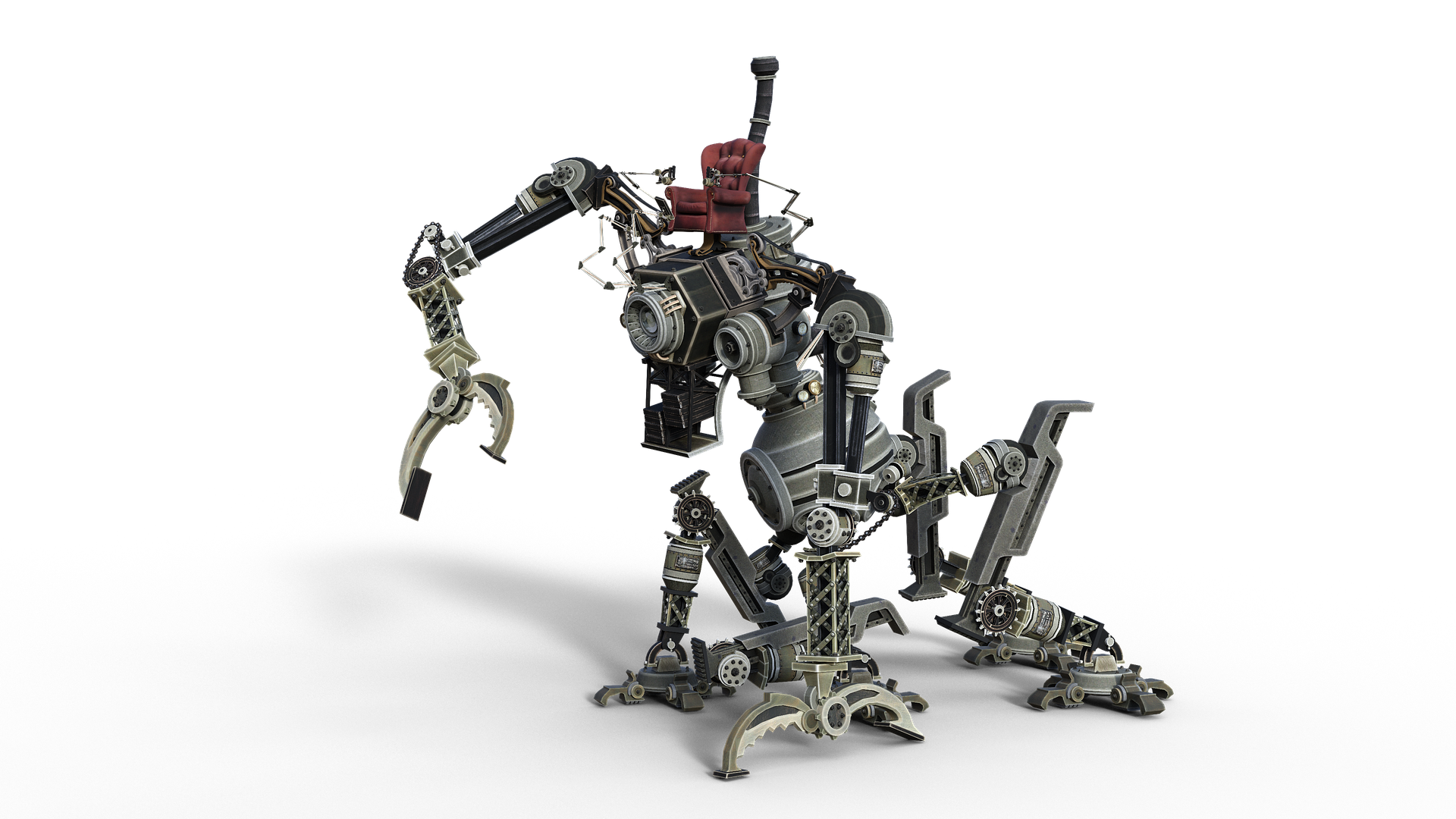

Concept: Danish company ‘Universal Robots’ has begun deploying and selling Collaborative Robots, also known as COBOTs, focusing on flexible automation for manufacturers of all sizes. COBOTs open access to many benefits of advanced robotic automation for manufacturers, without incurring any extra costs as opposed to traditional robots which are difficult to program and need long set-up time. This makes automation affordable even for small-batch production runs and mixed product assembly.

Nature of Disruption: COBOTs make automation easier today for several businesses. COBOTs can tackle labor shortages while improving crucial machine uptime. They help in loading and unloading machines and in assembling procedures such as screw driving, nut driving, part fitting, and insertion while reducing repetitive workplace injuries. They provide a flexible and efficient working environment for dispensing tasks such as gluing, sealing, painting. Polishing, buffing, and sanding tasks become more fine and accurate with COBOTs. They help in machine tending activities such as CNC, injection molding, press brakes, stamping presses, and simplify material handling, packaging and palletizing, bin picking, labeling, and kitting operations. COBOTs perform grinding, deburring, milling, routing, drilling, and other material removal tasks. They can consistently and repeatedly follow exact processes and pre-defined workflows with minuscule deviation, providing optimum conditions for study or analysis in projects. They can handle Arc, TIG (Tungsten Inert Gas), laser, MIG (Metal Inert Gas), ultrasonic, plasma, and spot welding, as well as soldering and brazing.

Outlook: Manufacturing success can be achieved when machines in a production plant keep on running. But often lack of skilled workers becomes a challenge for manufacturers, for the production line and supply process. Also, it can be troublesome to find and retain workers for tedious and possibly dangerous jobs such as machine tending operations. The Automation industry can help to overcome many of these issues. Automated collaborative robots are proven as cost-effective and safe mediums for use in the manufacturing and warehousing sectors. They offer flexible ways to deploy and roll the tasks easily with fewer labor needs and high productivity. COBOTs can make automation easier than ever, even for small and mid-sized companies around the world.

This article was originally published in Verdict.co.uk