Florida Power & Light (FPL) decommissioned and demolished its Riviera Beach Energy Center in June 2011 to make way for a new state-of-the-art combined-cycle natural gas power plant. The new plant, known as the Next Generation Energy Center, has an installed capacity of 1,250MW, which is sufficient to power approximately 250,000 homes and businesses.

Construction of the $.31bn project commenced in the first quarter of 2012 and was completed in early 2014, two months ahead of schedule. The plant was commissioned in April 2014.

The Next Generation Clean Energy Center will have an operational life of 30 years and will produce 600MW more than that of the Riviera Beach Energy Center.

The project is a part of FPL’s strategy to become the leader of clean energy in the US.

The new plant will reduce carbon-dioxide emissions by nearly 50%, which will be equivalent to taking off the road 46,000 cars a year over its life span.

The project provided economic benefits to the Palm Beach County by creating 950 direct jobs at the peak of construction. It will also generate revenue of $25m to Palm Beach County and local governments in its first full operational year in 2015 and more than $350m revenue to the County over the plant life.

Riviera power plant details and history

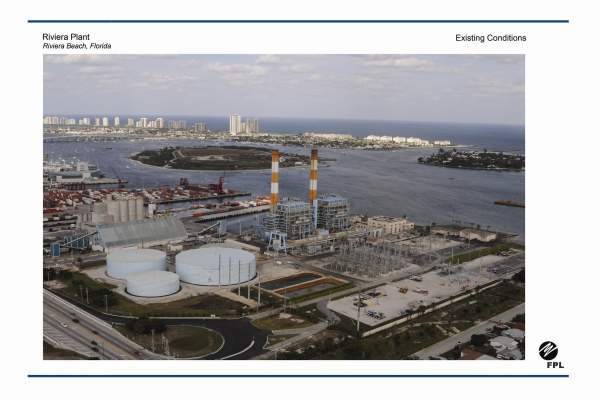

The Riviera Beach Energy Center, formerly known as Riviera power plant, was commissioned in 1946 with a 40MW Unit-1. The old plant was built on a 39 acre site to the southwest of the Palm Beach Inlet and Peanut Island. It was built across the Intracoastal Waterway from Palm Beach.

The 70MW unit-2 was added to the plant in 1953, followed by unit-3 in 1962 and unit-4 in 1963.

The plant consisted of four fuel storage tanks and water intake and discharge structures.

Units 1 and 2 were retired while units 3 and 4 continued to operate. The two units produced 300MW by burning fuel oil. They were supplemented with 600MW steam turbines.

Next Generation Energy Center project

The Next Generation Clean Energy Center project involved decommissioning and demolition of units 3 and 4 of the Riviera Beach Energy Center. It also required deconstruction of the fuel storage tanks.

The modernised plant is sleek and has 149ft tall stacks. It is more efficient than the old plant. It is equipped with 265MW SGT6-8000H combustion gas turbines which use 33% less fuel to produce the same amount of energy.

The new plant uses ultra-low sulphur light oil as back-up-fuel and make use of the existing intake and discharge structures of the Riviera Beach Energy Center. It sources water from the Intercoastal Waterway for cooling purposes.

A natural gas compression station has been built near the project site, on the south of the 45th street and to the west of the Interstate 95.

An office building featuring rooftop solar panels and an electric-car charging station are built. FPL expects the project will receive the US Green Building Council’s LEED certification for environment sustainability.

Development of Florida Power & Light’s (FPL’s) combined-cycle natural gas power plant

The project was announced in April 2008 and the site certification was received subsequently in November 2009.

FPL started deconstruction of Riviera Beach Energy Center in December 2010. The twin stacks and boilers were decommissioned and demolished in June 2011. The deconstruction activity was performed by Controlled Demolition, a US company.

The engineering, procurement and construction (EPC) contract for the Next Generation Clean Energy Center was awarded to Zachry Holdings in January 2011. The company provided engineering and procurement services from its Amarillo office in Texas. It appointed local labour from the Palm Beach County for construction purposes.

Plant make-up of the Next Generation Clean Energy Center

The Next Generation Clean Energy Center is comprised of three 265MW combustion engines with evaporative inlet cooling, three heat recovery steam generators (HRSG) equipped with selective catalytic reduction (SCR) reactors, one 500MW steam electrical generator and distillate fuel oil storage tank of 6.3 million gallon capacity and a 500 gallon fuel oil storage tank.

Other ancillary equipment include a permanent auxiliary boiler of 85,000 lbs/hour capacity, a temporary boiler used during construction, two 2,250KW liquid fuelled emergency generators and process heaters, a 300hp diesel fire pump and a gas compression station with seven 1,340hp natural gas compressors.