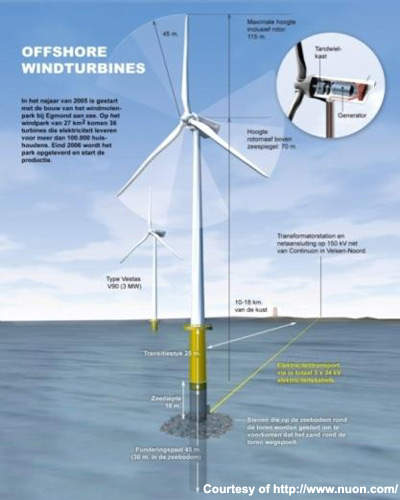

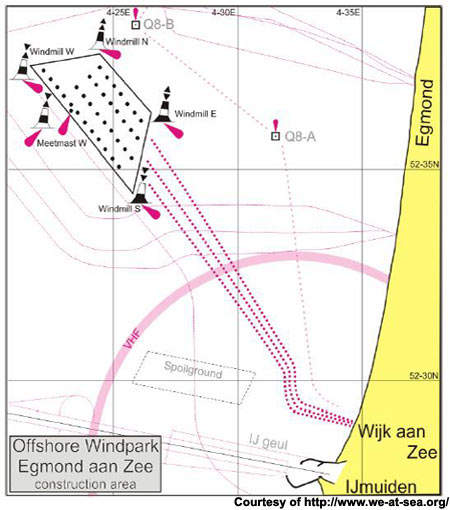

The Egmond aan Zee offshore wind farm (OWEZ) now has 36 Vestas V90-3.0 turbines producing 108MW. The project cost more than €200m, and was the first big wind farm to be built off the Dutch coast in the North Sea. Located 10 to 18km from the coast, the wind farm covers around 27km² and is just visible from the coast when the weather is fine.

Egmond aan Zee was opened in October 2007, and generates enough electrical power for about 100,000 Dutch households – a town the size of Eindhoven. It has been designed to last for 20 years.

EGMOND MANAGED BY JOINT VENTURE

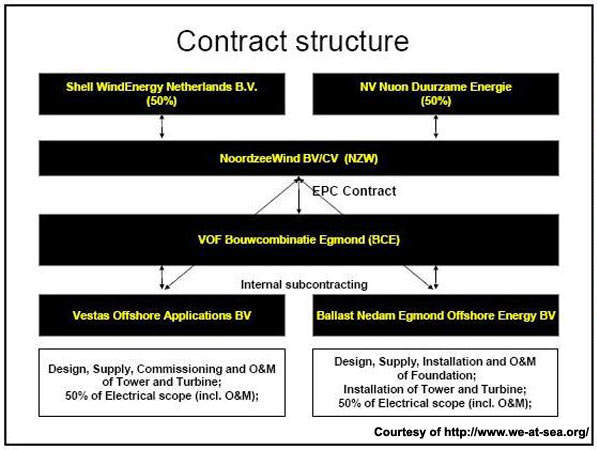

The Dutch government started the tender procedure in 2001. NoordzeeWind (a joint venture by Shell and utility company Nuon) signed the concession agreement, surveyed the sea bed and took wind measurements. In May 2005 Shell and Nuon signed the contracts.

NoordzeeWind subcontracted construction and day-to-day operational management to Bouwcombinatie Egmond (BCE), a partnership between Ballast Nedam and the Danish wind turbine manufacturer Vestas. The heavy-lift vessel Svanen sank the steel foundation piles. Measurements were taken regularly during pile driving to ensure that the pile was completely vertical. The masts of the turbines were then erected using a floating crane.

The turbines took around two days each to erect. The new harbour in Ijmuiden, the IJmondhaven, which opens directly to the sea, was used as the logistical base.

DUTCH OFFSHORE WIND DEMONSTRATION PROJECT

Offshore wind turbines are exposed to tough conditions, with a combination of salt, seawater, waves, currents and strong wind. To be able to make future farms cheaper and more efficient, more knowledge is needed about the effects those conditions have on the turbines.

There has also been insufficient data on potential effects on nature and environment in the Netherlands. The Egmond aan Zee wind farm is therefore linked to a comprehensive Monitoring and Evaluation Programme (NSW-MEP). This research programme started during construction in 2006 and will run until 2012.

The experience gained from the project will be used to develop wind energy in the Netherlands, and the Dutch Ministry of Economic Affairs has designated the farm as a Demonstration Project. The Dutch government has supported the project in three different ways: via the Environmental Quality of Electricity Production (MEP) scheme, an investment subsidy under the CO2 reduction plan, and by tax relief.

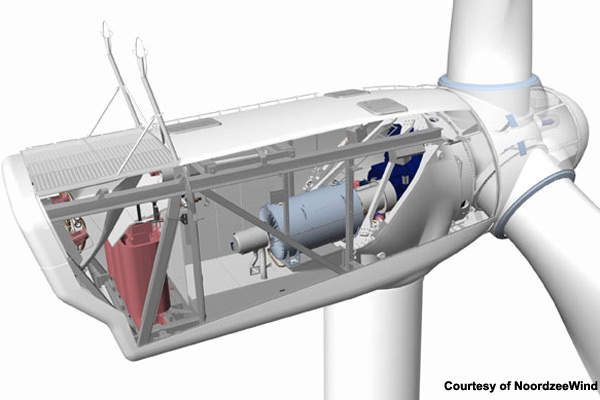

The 3MW turbines have a 90m rotor diameter and a 70m hub height. The 45m long blades are produced in Germany and transported by truck. They are attached to the main shaft, which is geared up to drive the generator. The electricity generated is stepped up to high voltage by a transformer in the turbine.

YEARLY TURBINE MAINTENANCE

The turbines need yearly maintenance, which is planned in for when the wind is weak. It includes inspections, lubricating rotating parts and replacing worn parts. A wind turbine can run for a total of 8,760 hours a year, depending on the site.

In addition to the planned maintenance, it is likely that a turbine will have to be visited three or four times a year to repair any breakdowns.

Maintenance is also carried out once a year on the foundations, the undersea cables and the transformer substation. This consists principally of visual inspections and underwater video recordings.

The farm is connected to the transformer sub-station on shore by three 34kV electric cables, each around 15.5km long. The substation is connected to Continuon’s national electricity grid by a 7km long underground high voltage cable. It goes from the transformer substation at Wijk aan Zee through Beverwijk to the substation close to the Nuon power plant in Velsen-Noord.