The pioneering Reykjanes Geothermal Power Plant in Iceland is now producing 100MWe from two 50MWe turbines. The plant uses steam from a reservoir at 290 to 320°C – the first time that geothermal steam of such high temperature has been used to generate electricity on a large scale.

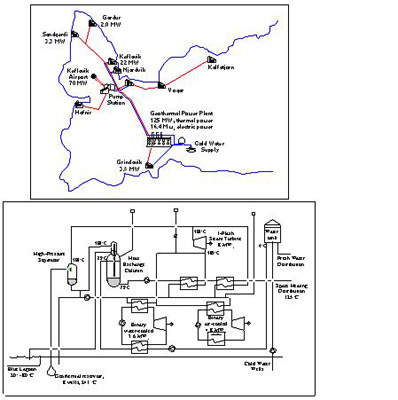

The new plant is located on the Reykjanes peninsula, in the south-western corner of Iceland. Owned by Sudurnes Regional Heating Corporation, the plant was designed by Enex, a conglomerate from the Icelandic energy sector with wide experience in developing geothermal energy and hydropower. The two turbines started operation in May 2006 after testing and were formally brought on-line in December 2006.

HIGHEST TEMPERATURE YET FOR GEOTHERMAL STEAM

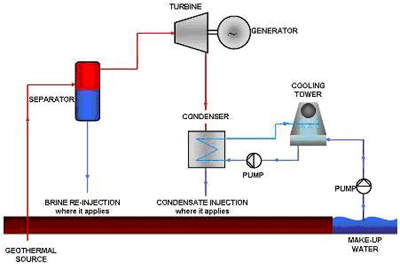

The Reykjanes plant uses steam and geothermal brine extracted from twelve 2,700m-deep wells. After extraction, the brine is piped into a steam separator. From there, the separated steam passes under 19 bars of pressure to a steam dryer and into the two 50MW turbines.

The plant is situated close to the ocean front, so seawater (4,000l/s) at 8°C can be pumped through a condenser for cooling and condensing the brine.

NEARLY 20% OF ICELAND’S ELECTRICITY FROM GEOTHERMAL

Geothermal resources have been used for over 70 years in Iceland. The geothermal area at Reykjanes is located on top of the Mid-Atlantic Ridge, formed by plate tectonics that are moving in separate directions. That gives high geothermal energy, with the Reykjanes area being where the plate boundary of the Reykjanes Ridge comes on land. The area is about 2km2 in size. Energy has been extracted from the area for around 30 years without significantly reducing the geothermal reserves.

Geothermal power plants produce nearly 20% of the country’s electricity; geothermal heating also supplies nearly 90% of the country’s domestic heating and hot water requirements. Nearly all the rest comes from hydroelectric generation, with less than 0.1% from fossil fuels.

Geothermal brine cannot be used directly for heating because of its high mineral content. On cooling, it releases great quantities of hard deposits (silica) which block pipes and other equipment. The high temperature and salt content of the water therefore demands heat exchangers.

DRILLING DEEPER WELLS

There are plans to enhance the power output of geothermal wells by exploiting the deeper, supercritical part of hydrothermal systems. This will require wells between 4 and 5km deep to reach temperatures between 400 and 600°C. In December 2003, a well (named RN-17, on the south side of the Reykjanes borefield) was drilled to just over 3km. However, it became plugged during a flow test in November 2005. Attempts to recondition the well in February 2006 failed due to caving of the formation, and it was abandoned.

Since December 2003, the pace of development of geothermal resources in Iceland has accelerated enormously. Besides the 100MWe of new production coming on line at Reykjanes, there is 90MWe at Hellisheidi and plans to supply electricity to a 250kt/y aluminium smelter near Husavik. These developments have led to the drilling of many new production wells at Reykjanes and Hellisheidi, with more planned in the next few years at these sites and at Krafla.

Since 2003, however, the cost of drilling services and well completion materials has risen sharply on the worldwide market, and there has been a long lead time (up to nine months) for valves and casings. Drill rigs have also become scarcer because of increased drilling levels.

Reykjanes is the only high-temperature, seawater-recharged geothermal system on a mid-ocean ridge available for deep drilling anywhere in the world. International interest and support for this drilling is high among scientists working on seafloor hydrothermal systems and ore deposits. Significant funding has come from the International Continental Drilling Program (ICDP) and from the US National Science Foundation (NSF) to obtain drill cores.

ADVANTAGES OF GEOTHERMAL

Geothermal is a sustainable energy source both for urban and rural areas, boosting local economies with minimum (and reversible) impact on the environment. The technique can provide earnings for over 30 years, producing baseload electricity with high reliability and availability. There is virtually no CO2 release and no impact on air quality.

The technique makes areas less dependent on polluting and increasingly expensive imported oil and fossil fuels, which are replaced with a renewable alternative with stable energy prices. It can also provide district heating for communities.

Geothermal needs a steady source of heat from 180°C upwards. It also needs a supply of make-up water, or adequate ambient conditions for dry cooling. The geothermal fluid normally reaches the surface as a two-phase mixture of steam and water.

The water fraction of the mixture must be removed before the fluid is sent to the turbine, both to increase the gaseous flow and to avoid damage to the turbine. The gaseous flow is then directed to the turbine where electricity is generated.

Different cooling systems are available in Enex single-flash power plants, including wet cooling towers, air cooled condensers or direct water cooling. The type of cooling system depends on availability and nature of cooling media at the site.

A double-flash cycle can be used if the brine temperature and pressure are adequate, with the medium pressure steam from the second flash chamber injected to the turbine at an intermediate stage. The steam exits the turbine as a saturated mixture and enters the condenser. The liquid brine exits the condenser and can be injected to where it is being used (for example, for district heating).

Enex can build turnkey plants, and allows contracts for BOOT (Build-Own-Operate-Transfer), BLT (Build-Lease-Transfer), BOT (Build-Operate-Transfer) or BOO (Build-Own-Operate).