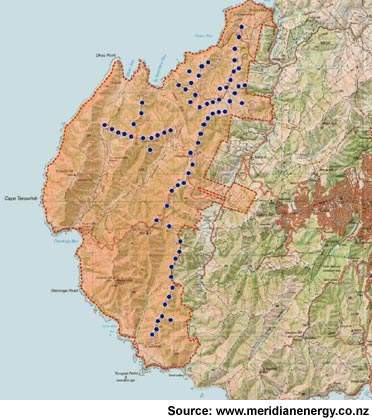

The West Wind wind farm is located on the Terawhiti Station (Sheep Station) and the Makara Farm, 15km west of Wellington, New Zealand. The farm constructed by Meridian Energy (Meridian) has a generating capacity of 142.6MW. Construction of the wind farm began in October 2007 and was completed in October 2009.

The project has cost about NZ$400m, with its planned size having been reduced from 210MW to 140MW because of rising steel and turbine prices. The wind farm has 62 turbines (supplied by Siemens), each of 2.3MW capacity, and will generate energy that will be sufficient to power 70,000 homes.

The first 15 turbines were operational by April 2009, while the remaining 47 turbines became operational in October 2009. All the turbines are connected to the national grid.

First large Pacific order for Siemens’ SWT-2.3-82

This was the first large order for the Siemens Wind Power from the Pacific Region. The contract included installation, start up, project management and a two-year service agreement.

The SWT-2.3-82 is Siemens’ preferred wind turbine for utilities and other large developers. The turbines were delivered at the end of 2008, with blades and nacelles shipped from Denmark.

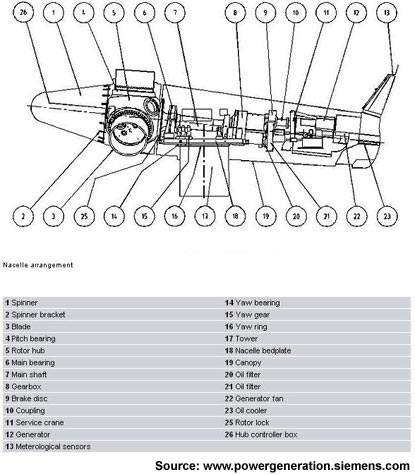

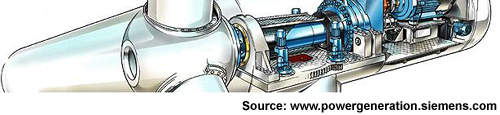

The design is similar to Siemens’ earlier MW models. The rotor has a three-blade cantilevered construction, mounted upwind of the tower. The power limitation is regulated by active stall regulation according to Siemens’ proprietary CombiStall system.

The blades are made of fibre glass reinforced epoxy and are manufactured in a single operation. There are no glue joints between spars and shells, no weak points and no easy access for water or lightning. The blades are mounted on pitch bearings and can be feathered 90° for shutdown. Each blade has its own independent fail-safe pitching mechanism that can feather the blades under any operating condition, and allowing fine-tuning to maximise power output.

The three-stage planetary-helical gearbox is mounted on the nacelle with flexible rubber bushings for compact construction and low noise levels. The gearbox is fitted with a fail-safe mechanical brake at the high-speed shaft.

The generator rotor construction and stator windings are designed for high efficiency at partial loads. The generator has separate thermostat-controlled ventilation. Efficient cooling allows the generator to work at low temperatures for increased lifetime of the winding insulation.

The SWT-2.3-82 turbine is mounted on a tapered tubular steel tower. This has internal ascent and direct access to the yaw system and nacelle. The turbine attaches to a microprocessor-based industrial controller; similar to those in other Siemens wind turbines. The controller is self-diagnosing and has a keyboard and display for status readout and for adjusting settings.

Construction

The concrete foundations for the installation of all the 62 turbines were laid by September 2008.

The diameter of octagonal foundations is 15m while the depth is 1.5m. The material used in construction of each foundation included 48 tons of steel reinforcement and 370m³ of concrete. A low ring of bolts that readily received the turbine’s tower sections were adjusted in the concrete.

A temporary wharf of length 128m was also constructed at Oteranga Bay in order to barge the turbine components. The wharf will be dislodged after few years, further, its deck and piles will be recycled.

The project also involved construction of crane pads of dimensions 30mx22m. The 400-ton crane lifted the towers, nacelle and three blades by residing on the crane pad. The installation of wind turbines was carried out in phases, by Siemens Wind Power. Underground cable lines were laid to connect the turbines to the on-site substation.

Turbine operation and safety

The turbine operates automatically under all wind conditions. It will self-start at about 4m/s average wind speed, with a small generator winding connected to the grid up to around 7m/s wind speed. At higher speeds, the generator switches to the main winding. The wind turbine output increases roughly linearly with the wind speed until the wind reaches 13–14m/s. Here, the power is limited at rated power by CombiStall®.

The turbine has several redundant safety levels, with an independent pitch system for each of the blades. As a result, the turbine can shut down safely from any operating condition. A WebWPS SCADA system offers long-distance control and a variety of status views and reports from a standard internet web browser.

The SWT-2.3-82 turbine can be supplied with an automatic power factor correction system, and the turbine has ride-through for all normal faults.

Grid network

The energy generated by the wind farm will be supplied to the national grid.

The power generated by the each turbine will be transmitted to the on-site substation through an underground 33kV network. At the on-site substation, the voltage will be stepped up to 110kV, by a step up transformer.

The stepped up voltage will then be transmitted to the Wilton-Central Park circuit transmission line by using a short overhead transmission line.

New Zealand plans carbon neutral generation for 2025

In 2007 the New Zealand government announced the intention to make its electricity sector carbon neutral by 2025.

Around 90% of electricity supply will come from renewable energy sources, with wind power playing a major role.

State-owned Meridian Energy is New Zealand’s largest electricity producer. It already supplies more than one third of New Zealand’s electricity demand using only hydro and wind power.

Wind energy is currently under-used in New Zealand. Even with Te Äpiti and other wind farm extensions, by the start of 2005 only 2.5% of electricity was generated by wind.

A study commissioned by the Ministry of Economic Development and the Energy Efficiency and Conservation Authority showed that if economic and resource consent conditions were favourable, wind farms could provide around 35% of the country’s present electricity needs.

It is estimated that Project West Wind will power up to 70,000 average homes, enough to power all the houses in Wellington City, Lower Hutt and Porirua.