The US$40m expansion of the Mokai geothermal power plant to 100MW is complete. The Geothermal Combined Cycle configurations use both the steam and brine components of the geothermal fluid.

The expansion came after careful monitoring of the existing 60MW station, and over 250MW is eventually planned at the site. Electricity is delivered via a 20km, 110kV line to the Whakamaru national grid substation and sold into the national pool. During the first six months of operation the plant generated an average output of above 58MW with an availability of above 96%.

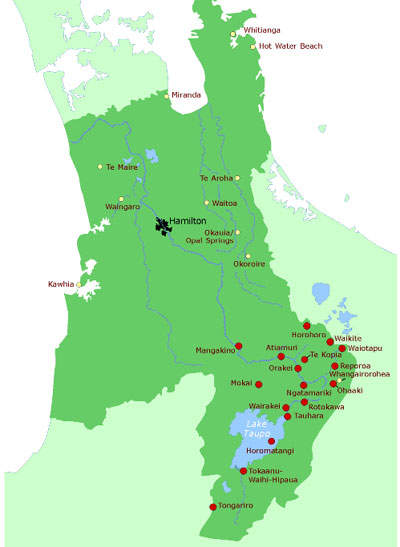

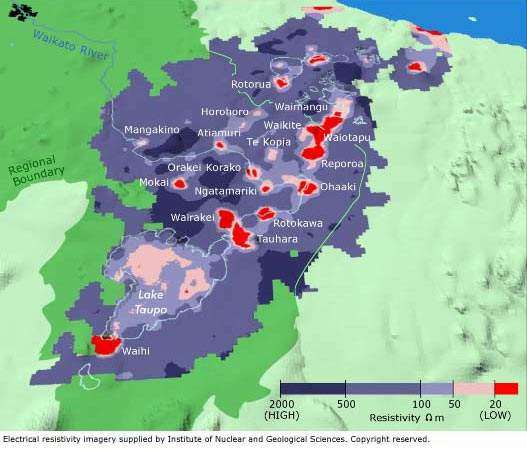

Extensive high-pressure geothermal resources in New Zealand

New Zealand lies in the Southwest corner of the Pacific “ring of fire” chain of volcanic activity and has extensive high-pressure geothermal resources. The main geothermal area is centred near the towns of Taupo and Rotorua.

The original settlers of New Zealand, the Maoris, used the natural geothermal springs for bathing and the very hot springs and geysers for cooking. The region saw some of the world’s early geothermal development, with the first station starting construction in the mid 1950s.

Several projects have followed the deregulation of the New Zealand electricity industry, with Mokai being New Zealand’s largest privately developed geothermal project. Uniquely, it is owned by the indigenous Maori people.

Geothermal fluid captured from wells

Mokai is a deep, high temperature field located approximately 25km northwest of Taupo. Four 2,000m-deep production wells produce steam and brine that are piped to a separator.

The Mokai plant uses a dual cycle generation scheme, the first being a steam-binary turbine combination and the second a lower-temperature brine unit connected to a second binary turbine. Steam is separated from the brine at 18bar and both the steam and the brine are used for electricity generation. The condensed steam is pumped up to the brine pressure, combined with the high-pressure brine and reinjected into 500m-deep reinjection wells with no further pumping.

Well chemistries indicate high temperatures for the production zones (350°C) and reservoir (325°C).

Back-pressure turbine

The original station uses a 32MW General Electric multistage back-pressure reaction-type turbine that reduces steam pressure to around 1.3bar. This low-pressure steam is condensed in four 6MW bottoming ORMAT® Energy Converter binary units. Two additional 6MW binary units use the hot brine flow, cooling it from 219°C to 150°C.

The generator circuit breaker, control and auxiliary electrical equipment for each binary unit is housed in a container and was delivered to site fully wired and pre-tested. This reduced construction time and sped up commissioning on site. The overall station control is from a control room attached to the steam turbine building. The central station control computer uses software and graphics developed by ORMAT.

The 42MW expansion has one 34MW Ormat Combined Cycle module working on geothermal steam and one 8MW Ormat Energy Converter unit working on geothermal brine. Efficiency of the Mokai II Plant is around 21%, achieved by employing high-efficiency organic vapour turbines recently developed by ORMAT.

The two Mokai power plants are the first stages of a modular, phased development and use approximately 40% of the available geothermal resource. The plants operate from a single central control room at the Mokai I plant.

Short mokai construction period

The modular nature of the plant allowed a very short construction period on site. All the binary turbines are mounted on simple low-level foundations. As the steam turbine has no attached condenser, it too is mounted on a low level foundation, allowing a relatively small turbine building.

The binary plant components were shipped in packages of standard container size and within days of the shipment arrival the main components were bolted down and the air-cooled condenser erection was under way.

Fletcher Construction (FCC) built 838m² structures for the original workshop, switchgear and control room/turbine/generator buildings. The buildings had structural steel portal frames with aluminium roof and wall cladding. A 13.5m-high turbine/generator hall was equipped with gantry crane and gland condenser annex was equipped with hoist. The structures used 32t of structural steel and used 2,252m² of cladding.

FCC also constructed 1,712m³ of foundations and building platforms with foundations for air coolers, OEC, accumulator and separator, turbine generator, muffler, pipe supports and building platforms for control/turbine/generator, workshop and switchgear buildings. The 245m³ pour for turbine generator foundation was completed in eight hours. These structures used 72.7t of reinforcing and 1,712m³ of concrete.

Low environmental impact

The station was designed to have minimal environmental impact. Under normal operating conditions the geothermal fluid is completely contained from production to reinjection. The only emissions are negligible quantities of steam emitted by the steam traps and the non-condensable gases emitted above the air coolers.

The plant has a relatively larger footprint but a much lower profile than a conventional condensing steam turbine with an underslung condenser. The air cooler structures have a significantly lower profile than wet cooling towers and have the advantage of never producing a visible plume. In addition to its low profile, the plant has no water or chemical consumption and no blow-down of contaminated cooling tower water.

Because the development was small relative to the ultimate capacity of the very deep resource, it had little impact on the surface features. A comprehensive baseline-monitoring programme was undertaken prior to project operation and an ongoing programme monitors the field behaviour.

Construction and long-term finance

The development was undertaken by the Tuaropaki Trust and is operated through its wholly owned project company the Tuaropaki Power Company.

The ORMAT group of companies was turnkey contractor and equipment supplier. Westpack Banking Corporation arranged the construction and long-term finance for the development. A contract for well drilling and testing was awarded to Century Drilling. Operation of the station is contracted to Mighty River Power.