A 670MW gas-fired thermal power plant is now operating at Ming-Hsiung Hsian in the Chia-Hui Province of Taiwan, some 200km southwest of Taipei. The plant was constructed by Electric Power Development Company (J-POWER) in collaboration with Asia Cement Corporation of Taiwan. The overall cost was 14.4 billion Taiwan dollars (just over €300 million).

Construction of the LNG Combined-Cycle plant began in January 2002. Commercial operation was initially planned for March 2004, but the project was actually completed three months ahead of schedule and commissioning was moved forward to December 2003. The entire power output is being sold to Taiwan Power Company (Taipower), Taiwan’s sole power operator.

GAS FIRED COMBINED CYCLE PLANT

The large-scale gas-fired CCGT thermal power station at Chia-Hui is JPP’s first IPP (Independent Power Producer) project in Taiwan. It was constructed under the Build, Own and Operate (BOO) method, with J-POWER investing in the Chia Hui project through its wholly-owned overseas investment company, J-POWER Investment Netherlands BV. The plant is run by Chiahui Power Corporation acting as local operating company. Under a Technical Support Agreement, J-POWER sent two of its engineers to Chia-Hui

to provide technical support during plant construction.

Asia Cement and its affiliates had an Equity Share of 59% in the project, with J-POWER taking 40% and other private shareholders taking slightly under 1%. Authorized capital of Chiahui Power Corporation’s Capitalization Fund was 4.3 billion Taiwan dollars (around €100 million), with another 4.3 billion Taiwan dollars of paid-in capital. Members of Troutman Sanders’ Project Development and Finance Group were also involved in project development and finance.

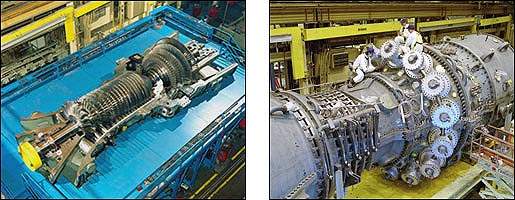

GE TURBINES

Operation and maintenance has been contracted out to General Electric (GE), which is also supplying advisory services and training for the project. The power station has three GE F-technology gas turbine-generators, shipped early in 2002. The turbines were introduced more than a decade ago, and GE has steadily increased their output and efficiency up to the latest version (Frame 9FB) with above 412MW at net plant efficiency of 58%.

All F class gas turbines include an 18-stage axial compressor and three-stage turbine and feature a cold-end drive and axial exhaust. This helps achieve net combined cycle efficiencies of over 58%.

The Integrated Gasification Combined Cycle (IGCC) gasification process “cleans” heavy fuels and converts them into high value fuel for gas turbines. The technology can satisfy output requirements from 10MW to more than 1.5GW, and can be used in almost any new or re-powering project with solid and heavy fuels. IGCC systems can be optimized for each type of fuel as well as site and environmental requirements.

To date, nearly 1,500 GE-technology gas and steam turbines have been installed or ordered for projects in the Asia-Pacific region, producing more than 136,000MW of power.

LARGEST ELECTRICITY WHOLESALER

J-:POWER is Japan’s largest electricity wholesaler. Established in 1952, the company focuses on developing power sources and building transmission lines. J-POWER sells electricity to Japan’s ten major electric power companies (EPCOs) from hydroelectric and coal-fired thermal power stations.

Since 1960, the company has participated in power projects in 59 countries, and has diversified its international operations through thermal and hydroelectric power developments. Activities include surveys, designs, construction management and technical assistance on environmental issues to independent power producer (IPP) projects.

The company has now developed 11 power plant projects (IPP projects) outside Japan. Ten of these are in service (total output capacity: approx. 2,070MW) and one is still in planning.