Four years ago, when General Electric’s (GE) president and CEO Steve Bolze went to Davos as co-chair of the energy committee, nobody was interested in the concept of a digital twin. “He likes to say they would have thrown him out if he talked about the idea,” says Sham Chotai, chief technology officer at GE Power & Water.

Four years ago, when General Electric’s (GE) president and CEO Steve Bolze went to Davos as co-chair of the energy committee, nobody was interested in the concept of a digital twin. “He likes to say they would have thrown him out if he talked about the idea,” says Sham Chotai, chief technology officer at GE Power & Water.

In 2017, that scepticism has almost entirely vanished. At last year’s Davos, the conversation “was all about digital”, Chotai says, adding that “Before people were scratching their heads and looking at GE saying, ‘Really, you guys are about software?’ Today, I don’t think anybody is doing that.”

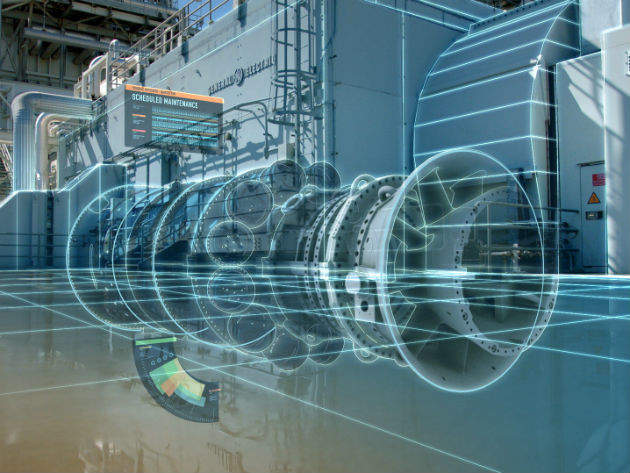

The concept of a digital twin works a lot like it sounds. Using data and intelligence, companies can get like-for-like digital representations of their physical systems, enabling them to understand, predict and optimise the performance of their businesses. “It’s a high-fidelity representation of your assets,” says Chotai, “a virtual model of machines using data and analytics.”

For trailblazers of the consumer internet, such as Google, Amazon and Apple, using data in this way is nothing new. “Think of it just like Amazon where you have a digital representation of yourself,” Chotai says, where data can reveal “buying patterns and different interests like the kinds of books that you read”.

Switching on the Industrial Internet

While the industrial internet has been relatively slow on the uptake, the benefits could be huge. “Here we are talking about devices, machines, systems, manufacturing processes, any process than an industrial may use,” says Chotai. “The data we are getting from these devices really dwarfs what we see on the consumer internet because there are just so many of these machines out there. We are talking about exabytes of data.”

Preventing machines from failing is one of the most obvious and potentially transformative applications the digital twin could have for the power sector. Recently, GE piloted a digital windfarm concept that uses a real-time simulation and modelling system to predict problems and optimise daily power production. The company says it could boost a farm's energy production by up to 20%.

“With windfarms we have put a lot of low-cost sensors on very heavy pieces of equipment and we want to be able to analyse that information”, Chotai says. “These turbines are expected to operate over a period of many decades in some of the harshest environments a machine can be subjected too. If they are going to fail, you want to know as soon as possible.”

In the wind sector, the digital twin can also offer a raft of other efficiency savings, Chotai adds. “It is a very unreliable fuel source,” he says. “It is not like nuclear, gas or coal where you know what output you are going to get depending on what you throw in. With the digital windfarm we are helping people do day-ahead forecasting, react to the markets and cope better with highly vertically integrated markets like North America and Europe, where you have got multiple fuel sources.

“It is about managing those renewables, signalling to the market what you can produce, and stabilising the grid across different fuel sources. That is the kind of technology that a digital twin allows us to put into play.”

And the digital twin is not just for turbines, but “all of the other parts of the power plant”, Chotai explains. “For instance, a compressor might fail. In the case of a nuclear plant, that can cause a scram and it can cost millions of dollars to bring a plant back online. Using the concept of the digital twin combined with deep machine learning we are able to predict 30 to 60 days ahead that a compressor will fail.”

“It’s like removing 300 million cars of the road”

Digital twins also provide environmental benefits. “If you have a coal plant or a gas fire plant and you save on fuel, not only are you providing an economic benefit you are providing a societal benefit as well,” Chotai says.

“The benefits we have seen with coal are incredibly significant. We improved the efficiencies of the plant by about 10%, meaning you need 80,000t less coal for a 10MW plant. If you scale that across the industry it is like not needing a force the size of Western Europe, or removing 300 million cars of the road. That is the size and scale we are talking about.”

As the power industry becomes more complicated and the workforce changes, Chotai says the digital twin concept is likely to attract more and more users.

“In the old days, you had an engineer listen to a turbine and know that something was wrong just by hearing it,” he says. “Today, you have got millennials wearing noise cancelling headphones listening to music. They think very differently and they work very differently. And it is not like before when you had centralised power generation.

“Now we have got municipalities and universities and other institutions that are also generating power. A lot of our customers are seeing this level of complexity and they know that it is really hard for a single human to be able to manage it. This is why there is so much interest in the digital twin.”